|

Special offer

CNC plazma

ATT Automatic cnc plasma characteristics

|

|

|

Current bid

5 axis

CNC milling machine

5 axis CNC milling machine features ATT machines

|

|

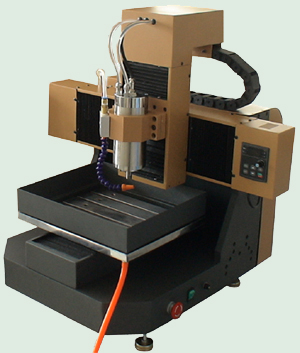

S30M CNC ROUTER

Overall:

It is bigger and faster providing you higher productivity than SC2518 Series. Once you have a level of understanding of the CNC router table and design software you will find that your dreams are possible regardless of your level of ability of machining. With a good design just secure your material and provide the CNC router with your design in G-CODE, HPGL CODE or ENG CODE. Our CNC router does the rest. The CNC router is well suited for the advertising industry, seal industry, craft and gift, art mould, wood working, mould etc. The materials that we recommend for our CNC router include acrylic, double-color board, PVC, ABS board, stone, imitation stone, Metal, Aluminum Mold etc.

Technical Parameter:

|

Drive Motor

|

Stepper System

|

|

X,Y axis Working Area

|

250mm*300mm or 10*12in

|

|

Z axis Working Area

|

120mm or 4.8in

|

|

Max Workpiece Width

|

430mm or 17in

|

|

Max Workpiece Length

|

500 mm or 20in

|

|

Speed of Cutting Feed

|

0-4000mm/min

|

|

Speed of Spindle

|

0-24000RMP

|

|

Power of Spindle Motor

|

1500W(Frequency Conversion Water-Cooled Motor)

|

|

Max Load on Workingtable

|

30KG

|

|

System Resolutions

|

0.003125 mm/Step

|

|

Positioning Accuracy

|

+/-0.01mm

|

|

Repositioning Accuracy

|

+/-0.01mm

|

|

Power Supply

|

220V-50HZ or 110V-60HZ

|

|

Driving Mode

|

TBI grinding ball screw /Taiwan

|

|

Guide Rail

|

LSK20 grinding linear square guideway/Taiwan

|

|

Collet

|

3.175mm, 4mm and 6mm OR 1/8“, 1/6" and 1/4"

|

|

Spindle Nose

|

ER11

|

|

Operation System

|

Professional NC Studio or DSP CNC System

|

|

Command Language

|

G CODE; HPGL CODE; ENG CODE

|

|

Machine Power

|

2KW

|

|

Net Weight

|

150KG

|

|

Software Compatibility

|

Wentai V8, Type3, Artcam, Artgrave and JDpaint etc.

|

|

Running Environment:

|

Temperature: 0 degC to 45 degC

|

|

Relative humidity: 30% to 75%

|

|

Optional Devices

|

Servo System, Vacuum Table, Forth Axis(rotary), Dusting System, High-precision Vice,etc.

|

Feature:

-

The machine body and the bottom jointed as a whole, little vibration of the machine, that makes the worktable steady and guarantee the machine working smoothly. Low noise, then the workpiece will be fineness.

-

The X, Y, Z-Axis adopt linear square guideway and ball screw to ensure high accuracy and high rigidity.

-

High position and Repeatability Accuracy, to ensure the edge of workpiece smooth and the workpiece in high definition.

-

High precision, high rotation speed and low noise of spindle motor, the radius run-out of the router bits(root of tool holder) 0.02mm, to provide higher cutting speed and better cutting ability of small cutter.

-

Professional and stable CNC system.

-

The feature of the moving is: high acceleration for initial starting, stable return motion,keeping higher & steady feeding speed and higher acceleration. Effectively improved processing efficiency, and the little vibration of the machine brings finess for the finished workprice.

-

English langugae control surface, it’s more visual and convenient for operation.

Application:

-

Suitable for processing metal material, such as brass, copper, aluminum, etc.

-

To be used to process or drill small precision components.

-

High accuracy copper electrode.

-

Various kinds of small mould and lettering.

-

Plate spectacles engraving, spectacle frame milling.

-

Metal spectacle frame milling.

-

Spectacles temple, bridge die.

-

Mobile phone, DVD pannel cutting.

-

Electronic jig.

-

Watch case electrode, drilling on watch case.

-

Small-size hand paddle.

-

Small-size space model.

-

Jade and crafts processing.

|

|

|

Navigation

|

|

|

|

Write to us!

|

|

|